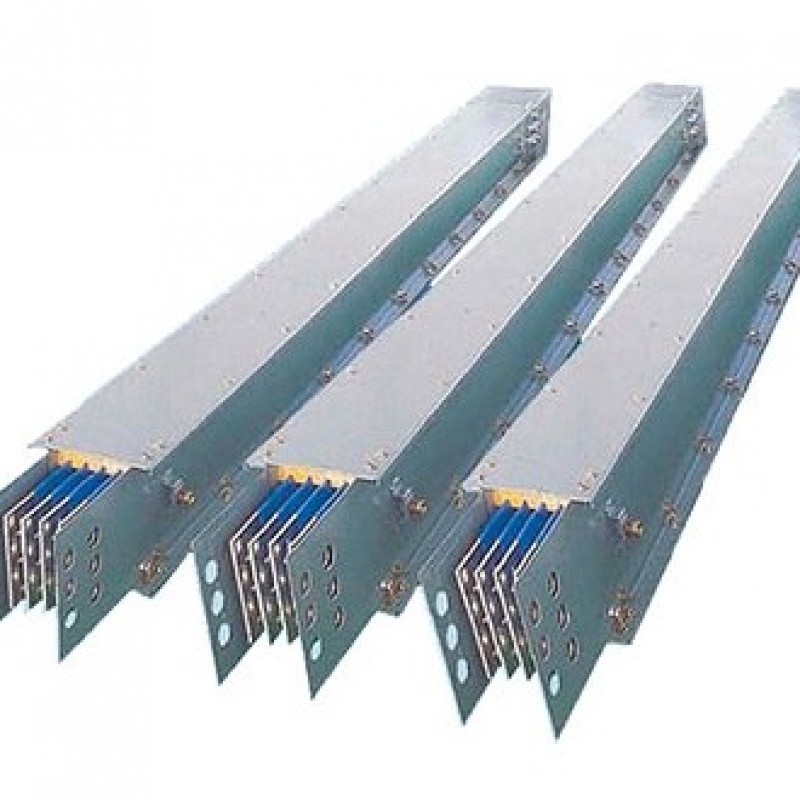

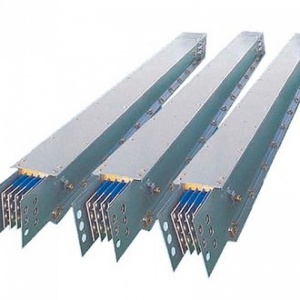

1, ZB1C bus conductor adopts high purity electrolytic copper, rectangular bronze copper content up to 99.95%, resistivity p ≤0.017777, conductivity up to 98%, in line with ASTMB152-97 and GB55851-3 standards.

2. The conductor surface can be tinned (silver plated) according to customer requirements, strong resistance to oxidation corrosion, reduce the contact resistance, so that its electrical contact performance fully meet high standards.

3. ZB1C bus system has the advantages of low voltage drop and low line loss due to the use of high quality copper or aluminum conductor and international leading new product structure design.

4. The conductor busbar is made of DuPont B class (130°C) bearing film (Mylar) as the whole insulation material. The flame retardant property meets the requirements of UL94 standard without any toxicity. It is a safe and environmental protection halogen-free insulation material. It is a professional electrical insulation material recommended by International IEC Association, which greatly improves the safety performance of the busbar groove. All products pass DC 7500V (1min) high voltage test before leaving the factory, and 100% qualified products will be handed to customers.